As the global demand for personalized and efficient packaging solutions continues to grow, the importance of choosing the right box-making machine manufacturer cannot be overstated. With China emerging as a prominent player in the manufacturing landscape and Europe maintaining its legacy of precision engineering, the choice between these two regions becomes a pivotal decision. In this blog, we will explore the factors that go into selecting a quality box-making machine manufacturer worldwide while addressing the equal quality of current machines from both China and Europe.

1. Research and Reputation

Begin your quest for a reliable manufacturer by researching their reputation and standing in the industry. Both Chinese and European manufacturers have proven their mettle with impressive offerings. Investigate their track record, reviews, and the opinions of those who have used their machines.

2. Technological Expertise:

European manufacturers are renowned for their technological prowess and precision engineering. Chinese manufacturers have also invested heavily in research and development, resulting in advanced and efficient box-making machines. Consider the level of technology integration, automation, and customization options each manufacturer offers.

3. Manufacturing Experience

European manufacturers often boast decades of experience and a strong tradition of craftsmanship. On the other hand, Chinese manufacturers have rapidly evolved and adapted to modern manufacturing techniques. The key here is to assess the depth of their experience, quality assurance processes, and their ability to adapt to changing market demands.

4. Customization Flexibility

One of the prime benefits of modern box-making machines is their ability to cater to unique packaging needs. Both Chinese and European manufacturers provide customization options. Evaluate how well each manufacturer can tailor their machines to suit your specific requirements.

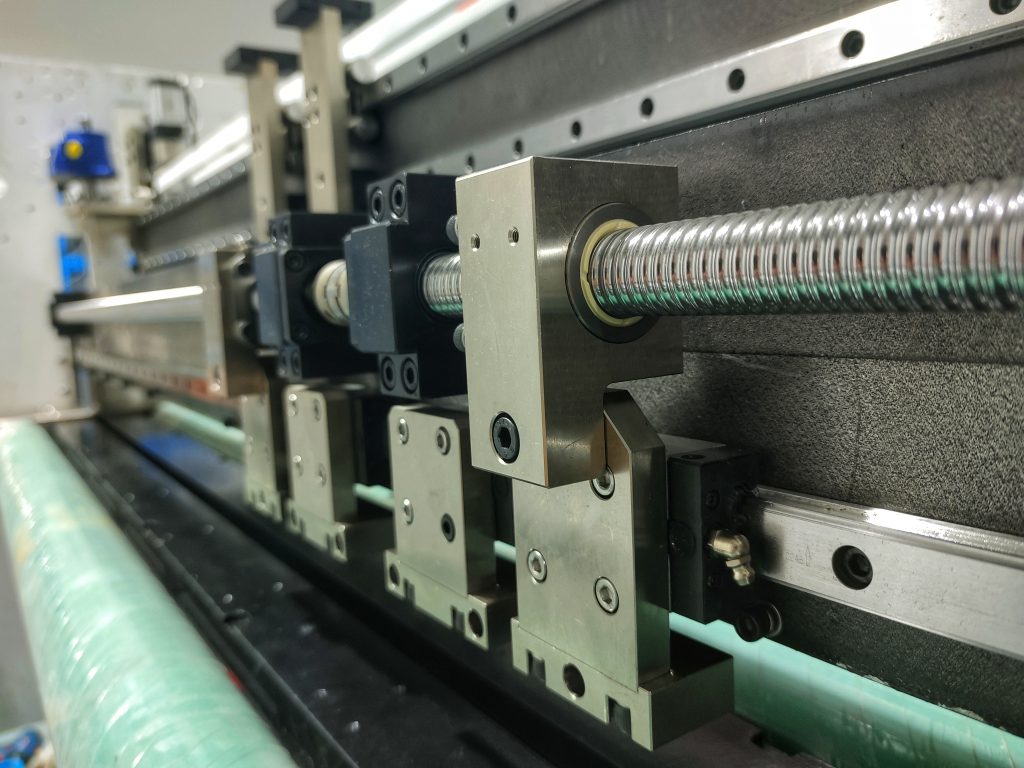

5. Build Quality and Durability

European manufacturers are known for their meticulous attention to detail, resulting in machines that often excel in build quality and durability. However, Chinese manufacturers have made significant strides in improving the robustness and longevity of their machines. Focus on the materials used, quality of components, and overall build to ensure a lasting investment.

6. After-Sales Support:

Excellent after-sales support is crucial to minimizing downtime and ensuring uninterrupted operations. European manufacturers often excel in providing comprehensive support, while Chinese manufacturers have also been enhancing their post-purchase services. Investigate their service networks, response times, and availability of spare parts.

7. Certifications and Compliance

Both regions have stringent industry standards and certifications. European manufacturers often tout their adherence to strict regulations, but Chinese manufacturers have also been aligning themselves with global standards. Prioritize manufacturers that exhibit a commitment to safety, quality, and compliance.

8. Cost Considerations:

Cost is an influential factor in any decision-making process. Chinese manufacturers tend to offer competitive pricing due to lower production costs, but this doesn’t necessarily translate to compromised quality. Evaluate the cost in relation to the overall value, including technology, customization, and long-term benefits.

9. Global Reach:

Consider the global reach of the manufacturer. European manufacturers often have established international networks, but Chinese manufacturers have also expanded their presence. A strong global reach ensures efficient support, no matter where your operations are located.

10. Customer References:

Request references from both Chinese and European manufacturers. Speak to businesses that have implemented their machines to gain insights into their experiences, challenges, and successes.

Conclusion:

In the realm of Anypack on demand making machines, both Chinese and European manufacturers offer high-quality options. The choice ultimately hinges on your specific needs, preferences, and long-term vision. By meticulously evaluating factors such as reputation, technological prowess, customization, build quality, after-sales support, and cost, you can make an informed decision that aligns with your business objectives. Remember that quality knows no geographical bounds; it’s the amalgamation of expertise, innovation, and customer-centricity that truly defines a top-tier box-making machine manufacturer.