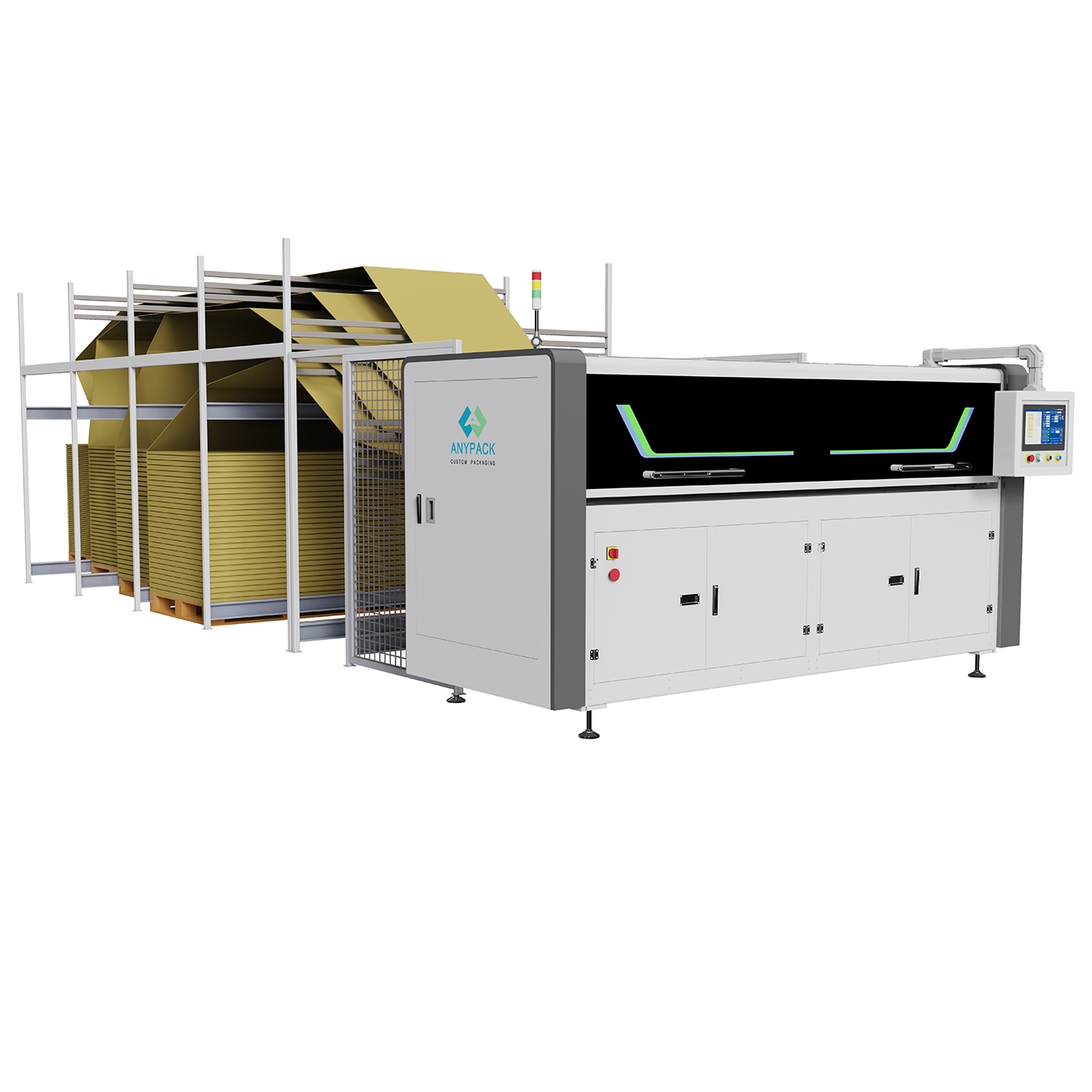

What is Anypack on demand machine

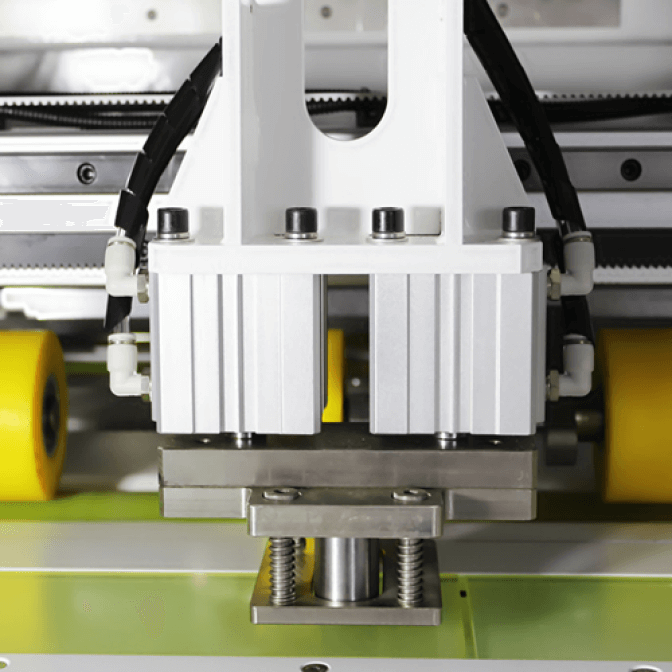

Feature slitting, slotting, creasing, scoring and trimming in one

compact machine.

Can make a box any time with any type and any size.

Changeover time 3-15 seconds.

One operator is enough.

Brief introduction

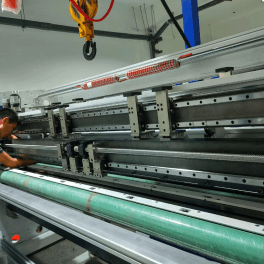

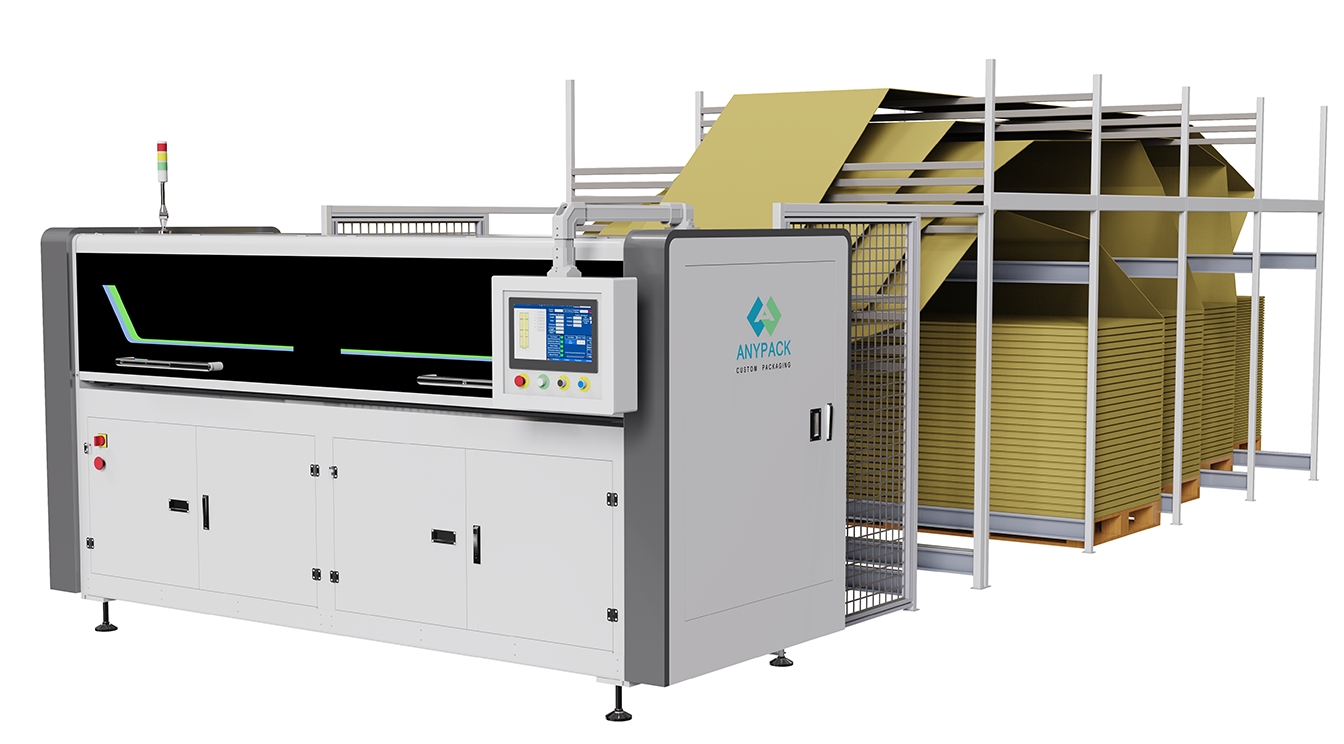

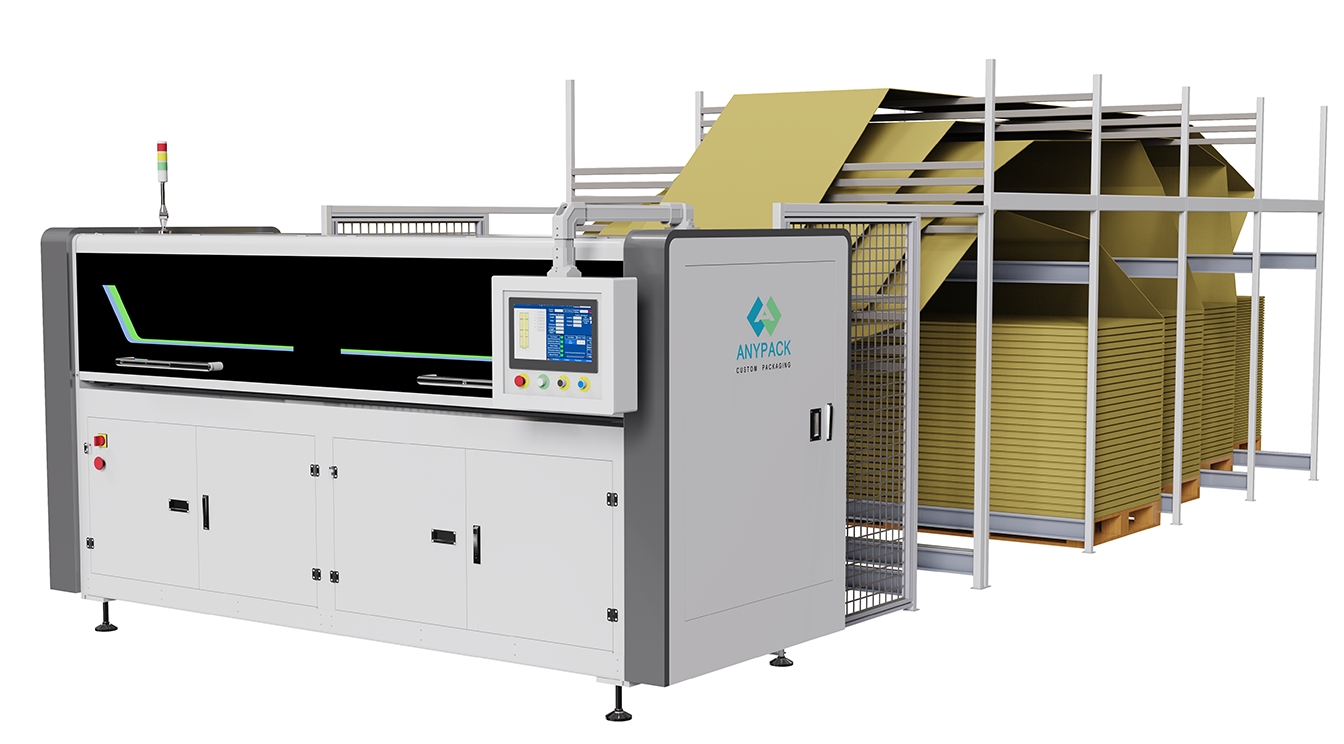

AB2500F packing on demand making machine is specifically designed to meet

the requirement of custom packaging.

With the features of fast switchover and relatively high productivity,

it is a leading player in the emerging custom packaging system.

It is applicable for e-commerce packaging, fulfillment center,

furniture, cabinet, manufacturing packaging, print marketing

Download Brochure

How will the anypack On Demand Making Machine bring you more benefits ?

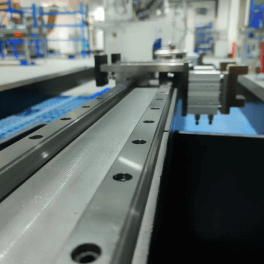

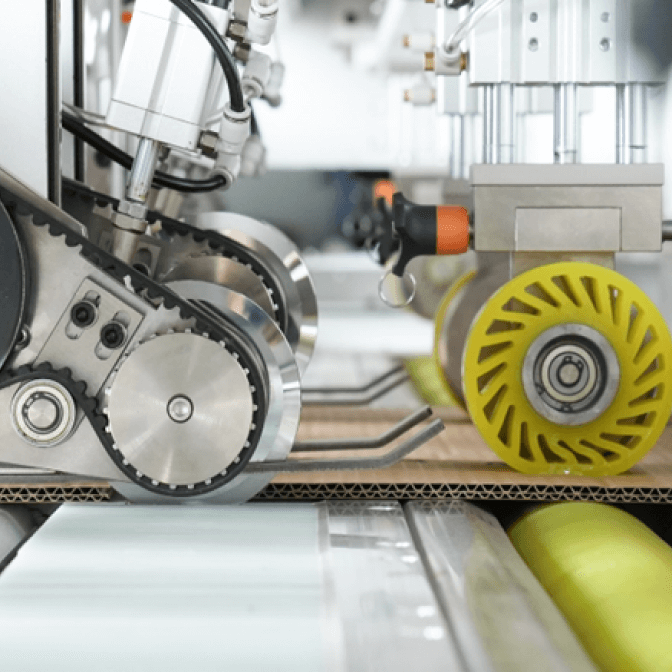

Designed on the basis of carton box machine AB2500, which retains the

slotting, creasing, and cutting functions.

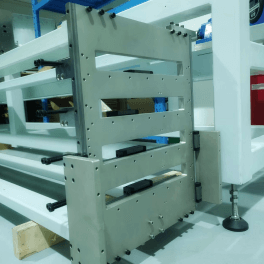

Support Z-shaped cardboard.

Any size, any style, just needs seconds,on-demand production.

Customized packaging solutions, avoid using fillers.

Labor-saving, cost-saving and easy-operated, all the settings just

need seconds.

Reduce carton inventory as well as management cost.

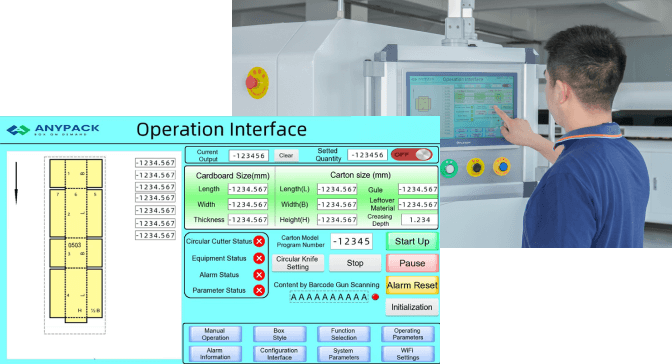

Operation System

Comes with four languages (Chinese, English, Spanish, Korean), can be

customized according to customers needs.

Can Keep 2000 Operation Records, no need to repeat the input.

Easy operation, the interface is clear and easy to understand.

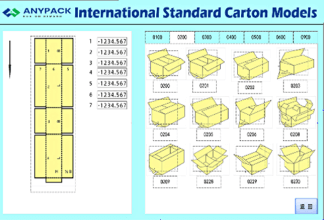

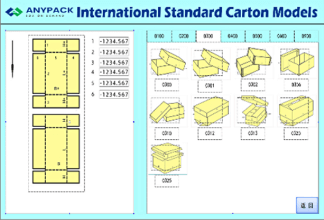

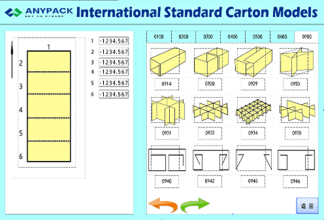

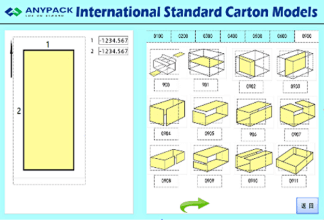

More than 85 box styles for your choice

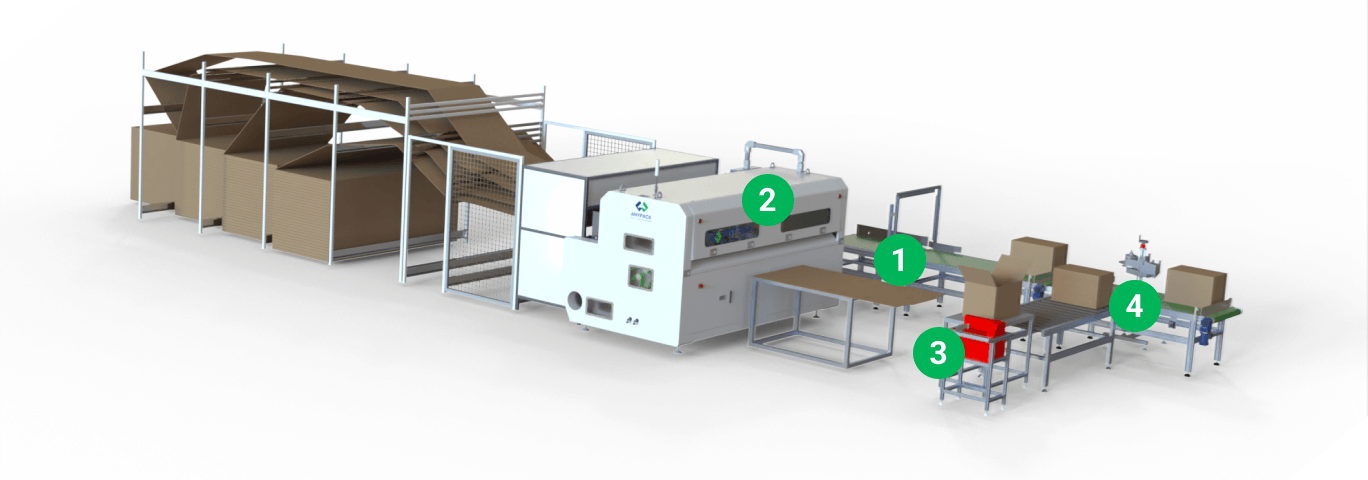

Integrated System packing On Demand

1. SCANNER: measuring station that detects the dimensions of a product

or a composition of products. It sends the data to the box machine,

which then automatically produces the correctly- sized box.

2. AB2500F: box machine with integrated PRINT ON DEMAND system(AP2500). This high resolution ink jet print system allows to simultaneously print and produce the box.

3. GLUER: glueing station for slotted boxes.

4. TRANSFER STATION: for the packed goods.

2. AB2500F: box machine with integrated PRINT ON DEMAND system(AP2500). This high resolution ink jet print system allows to simultaneously print and produce the box.

3. GLUER: glueing station for slotted boxes.

4. TRANSFER STATION: for the packed goods.

Specification

Download Brochure

Size

3500(L) ×1900(W)×5000(H)mm

Weight

5000kg

Power

380V, 50-60HZ, 32A,16KW

Production Rate

400 PCS/Hour

Sheet Type

Z-shaped Cardboard

Cardboard density range

Up to 1200g/m²

Max.board size

2500mm Width x Unlimited Length

Min.board size

200mm Width x 650mm Length

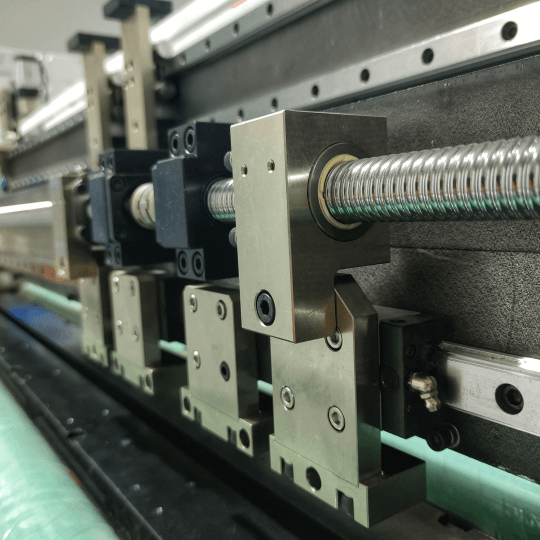

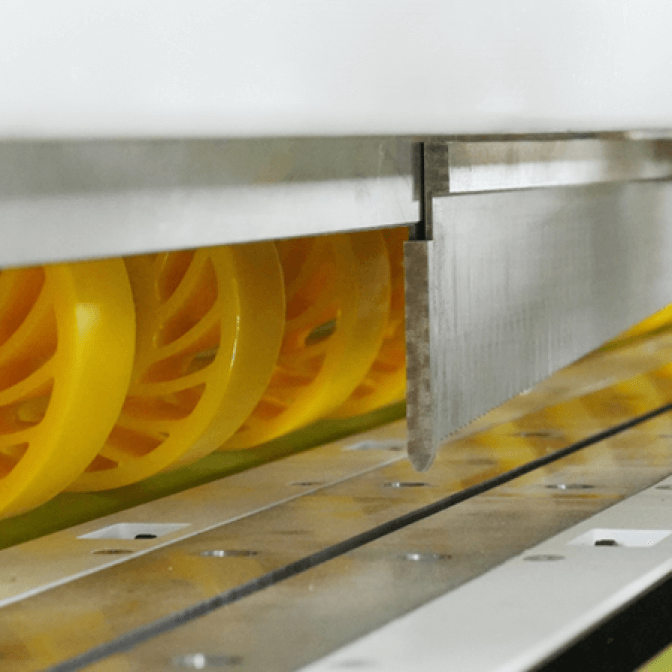

Slotting Knife

2 PCS *500mm Length

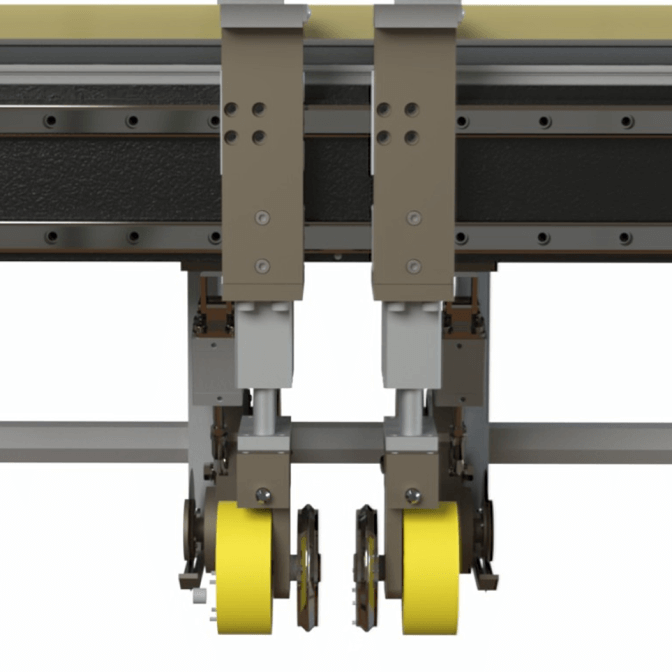

Servo Motor Qty

8 Sets

Max Sheet Size

2500mm Width, Unlimited Llength

Min Sheet Size

340mm Width, 700mm Length

Switchover Time

2-15 Seconds

Touch Panel

15.6 Inch

Cardboard thickness

2-10mm

Vertical Cutting knife

4

Scoring/Creasing Wheel

4

Horizontal Cutting Knife

1

Air Pressure

0.6-0.7MPa

Box styles

More than 85 Fefco codes