Function

Automatic Loading & Unloading

Size Measurement

Automatic Folding

Automatic Sealing

Labeling

WMS Integration

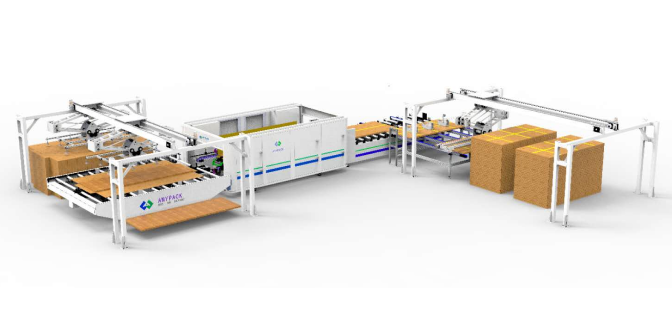

Fully Automated Packing and Sealing

Enables Automatic Loading and Unloading, Measurement, Box Folding, Sealing, Labeling, and More.

Seamless Integration with WMS system

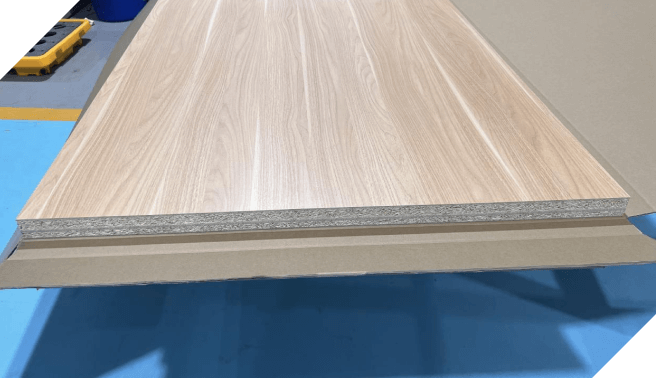

Custom-tailored to package precisely based on the dimensions of panels

Additional features like corner protectors and anti-collision strips can be added as per requirements

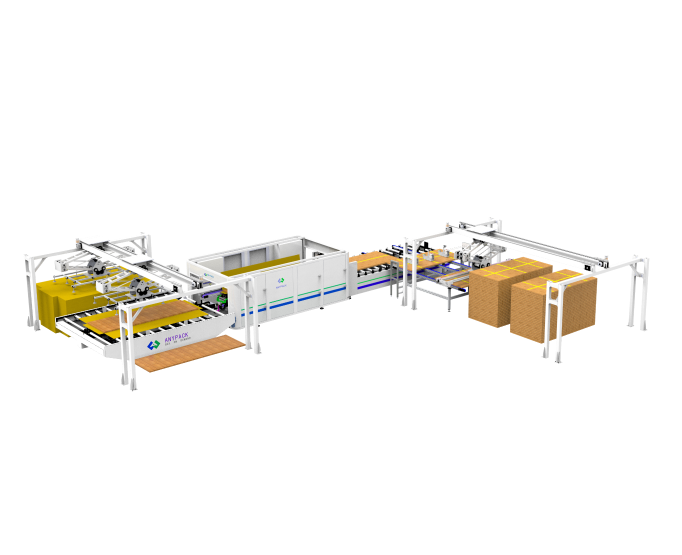

Panel Wrap Line—Panel Wrap integrated with Corrugated Box Making

Machine

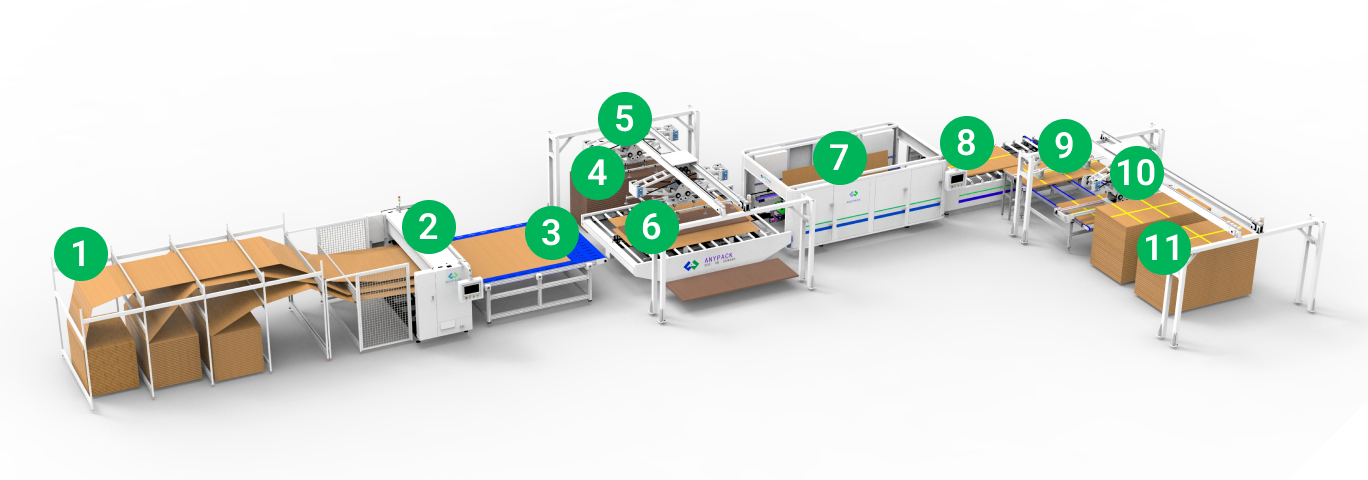

1.Z-shaped Paper Storage and Feeding Area: Stores Z-shaped paper or individual cardboard sheets, as

required. It automatically feeds materials as needed.

2. Carton Making Machine (AB2500F or AB2500): Customized,

real-time production of cartons in various sizes based on the dimensions of wooden boards obtained in

functional position 4.

3. Cardboard Conveying Area: After cutting, cardboard is

transported to the packing station using a conveyor belt equipped with adhesive functionality to prevent

shifting during transport.

4.Wooden Panel On Each Side

5. Wooden Panel Feeding & Dimension Measurement: Two sets

of feeding structures on the left and right ensure uninterrupted material feeding, enhancing efficiency.

These mechanisms also measure dimensions while gripping wooden boards.

6. Packing Area: Cardboard conveyed from position 3 is

automatically positioned in the packing area. An automatic positioning mechanism aligns the cardboard

with the wooden board’s center. After placing the wooden board onto the cardboard, the feeding structure

transports it to the next station.

7. Wooden Panel Packaging Making: This machine folds the

cardboard’s long and short sides, carrying the wooden board, and conveys it to the next station.

8. Tape Sealing (Lengthwise): Single-tape sealing in the

length direction.

9. Tape Sealing (Widthwise): Three-tape sealing in the

width direction.

10. Packed Panel Unloading: An automatic cutting

mechanism trims completed, packaged wooden boards and neatly stacks them (single or multiple stacks).

11.Packed Panel Storage Area: Storage area for completed

packages.

Specification

Download Brochure

Equipment Size

200000(L) ×14000(W)×2500(H)mm

Weight

Apprx. 11000 kg

Powder

220V, 50/60HZ,30KW

Air Pressure

0.6-0.8 Mpa

Capacity

160ctn/H

Carton Type

FEFCO 401& Customized(with protection corner folding structure)

Carton Sealing Type

Tape

Max Packaging size

3100(L)x1200(W)x40(H)mm

Minimum Packaging size

1500(L)x600(W)x27(H)mm

Max Load Weight

100KG

Control System(Software)

PLC(Keyence)

Gantry

Loading:1 Gantry with 2 vacuum grippers group for cardboard loading and wood panel loading

Unloading: 1 Gantry with bottom clamp

Unloading: 1 Gantry with bottom clamp

Material Loading

Automatic Material Replaceable station

Unloading

Automatic finished product Replaceable station

Protection Foam placement station

2 manual placement

Vacuum Grippers Quantity

8( Adjustable)

Logitudinal Sealing Machine

1

Transverse Sealing Machine

3